Achieving Superior Finishes with In-Mold Decorations in Manufacturing

Achieving Superior Finishes with In-Mold Decorations in Manufacturing

Blog Article

Grasping In-Mold Decorations: Techniques, Fads, and Best Practices for Optimum Outcomes

In the world of production, the art of in-mold decorations stands as an essential element of item layout and manufacturing. In-Mold Decorations. By diving right into the strategies, trends, and finest techniques that underpin effective in-mold decor procedures, organizations can open a realm of opportunities that not just boost the visual attraction of their items yet also simplify manufacturing performance and strengthen consumer engagement.

Product Choice

Product option is a vital aspect of mastering in-mold decorations, as it straight influences the high quality and toughness of the last product. When choosing products for in-mold designs, it is necessary to take into consideration variables such as compatibility with the molding procedure, the preferred aesthetic result, and the environmental conditions the item will certainly deal with. Thermoplastic materials like polycarbonate, polypropylene, and abdominal muscle are frequently utilized for in-mold decorations as a result of their convenience and capability to achieve complex styles. These materials supply exceptional moldability, allowing manufacturers to develop intricate shapes and patterns with accuracy.

Furthermore, products with high heat resistance are chosen for in-mold decorations, specifically for products that will certainly be subjected to elevated temperature levels during their lifecycle. By meticulously selecting the suitable product for in-mold decors, suppliers can enhance the overall high quality and resilience of their items, fulfilling the expectations of both customers and end-users - In-Mold Decorations.

Style Advancement

A crucial consider progressing the field of in-mold designs is the continuous exploration and execution of design innovation techniques. Design innovation plays a critical role in boosting the visual appeal, capability, and general top quality of products produced utilizing in-mold design procedures. By integrating innovative style components, suppliers can differentiate their products out there, attract consumers, and remain ahead of competitors.

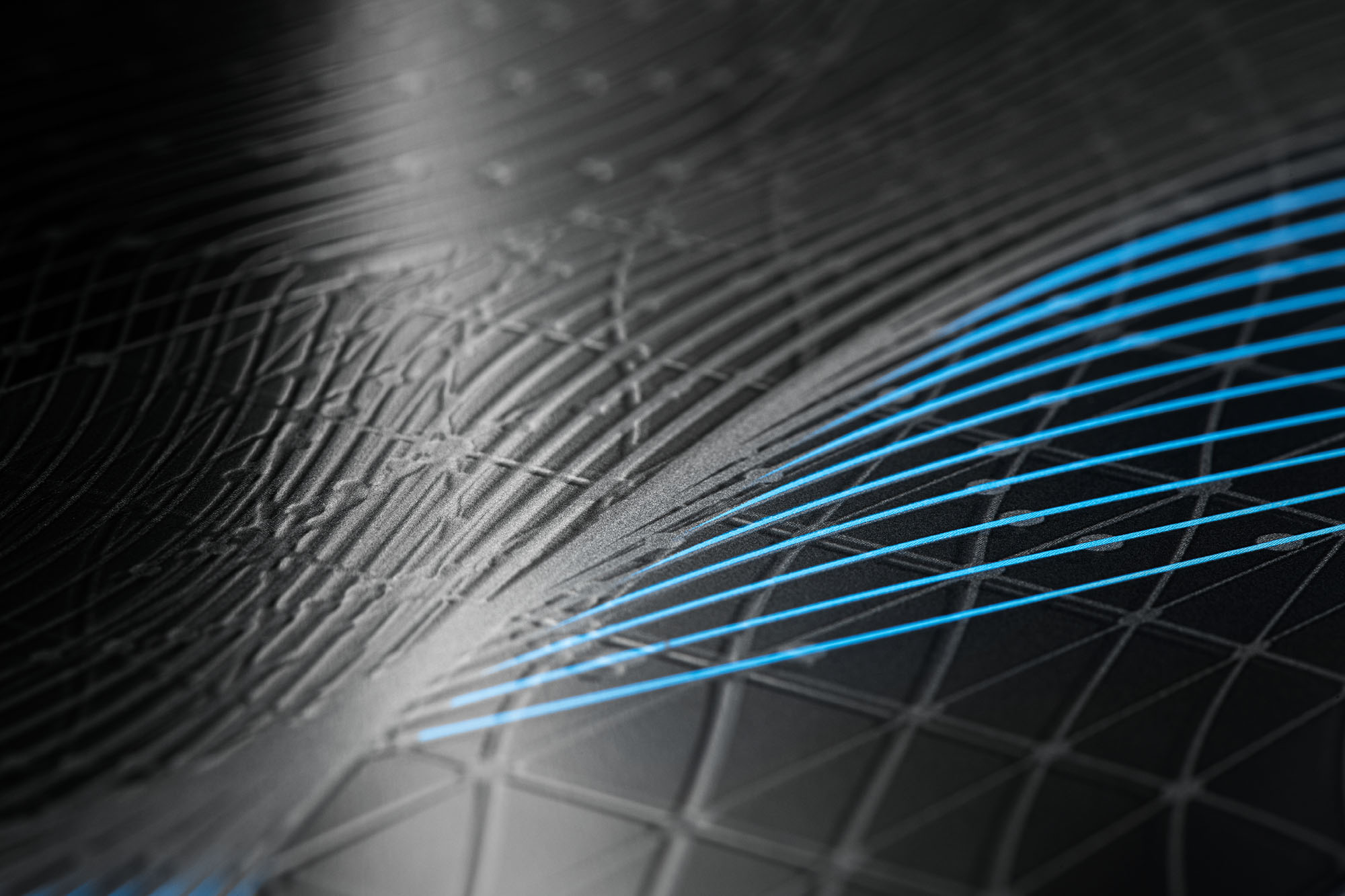

One of the essential elements of design development in in-mold designs is the assimilation of intricate patterns, textures, and graphics that were previously testing to attain with standard decor methods. Advanced innovations such as 3D printing and digital design tools allow designers to create complicated and comprehensive designs that can be seamlessly transferred onto molded components. Furthermore, using dynamic shades, metal finishes, and special results like gloss or matte structures can even more raise the aesthetic allure of in-mold enhanced products.

Moreover, style innovation expands beyond aesthetics to include useful improvements such as ergonomic forms, incorporated features, and adjustable elements that cater to details individual requirements. By embracing style innovation, suppliers can unlock brand-new possibilities for customization, imagination, and item distinction in the competitive landscape of in-mold decorations.

Manufacturing Effectiveness

Efficient manufacturing processes are necessary for equating the innovative designs established in the area of in-mold designs into top notch ended up products useful link that fulfill market needs and customer assumptions. In the world of in-mold decors, production efficiency encompasses numerous essential aspects that add to the overall success of the manufacturing procedure. One crucial aspect is the optimization of mold design and tooling to ensure exact and smooth decoration transfer onto the end product. By fine-tuning mold arrangements and purchasing top notch tooling materials, makers can improve efficiency and uniformity in manufacturing.

Automation not just accelerates the production process however also improves precision and repeatability, leading to a more uniform and top notch end item. On the whole, an all natural method to manufacturing efficiency is critical in taking full advantage of the possibility of in-mold decor techniques and achieving optimal results in the affordable market landscape.

Quality Assurance Actions

What are the crucial techniques for guaranteeing stringent top quality control measures in the world of in-mold decorations? Quality assurance procedures are vital in in-mold design processes to make certain the production of high-quality and remarkable ended up products. One important method is the implementation of extensive evaluation procedures at every stage of the production process. This entails conducting extensive visual examinations, dimensional checks, and shade consistency analyses to news determine any kind of inconsistencies or problems beforehand.

Utilizing innovative modern technologies such as computerized examination systems can likewise enhance the top quality control process by providing trustworthy and precise data for evaluation. These systems can identify blemishes that may be missed by hands-on examinations, thus improving general item high quality and consistency.

Regular training and advancement programs for employees included in the in-mold decoration procedure can likewise add to keeping premium criteria. By informing staff on best techniques, top quality expectations, and the significance of interest to detail, business can promote a society of quality consciousness throughout the company.

Customer Allure

To boost the bankability of in-mold decor products, providing and comprehending to customer choices play an essential duty in establishing their allure and success. anonymous Consumer appeal in in-mold decors is affected by different aspects, consisting of design appearances, shade selections, sturdiness, and overall functionality. Customers are significantly looking for individualized and one-of-a-kind items that show their uniqueness and style. As a result, supplying customization choices such as personalized designs, shade variants, and textural aspects can significantly improve the allure of in-mold design products.

Final Thought

In-mold decorations use a effective and versatile means to enhance product visual appeals. Mastering in-mold decorations calls for an alternative strategy that takes into consideration all elements of the production process to make certain success.

In the realm of manufacturing, the art of in-mold decors stands as a pivotal aspect of item design and manufacturing. Layout development plays an essential duty in improving the aesthetic appeal, capability, and general quality of products manufactured making use of in-mold decoration processes.One of the essential aspects of style advancement in in-mold designs is the assimilation of complex patterns, textures, and graphics that were formerly testing to attain with traditional decoration techniques.Efficient production processes are essential for equating the innovative styles developed in the field of in-mold decorations right into high-grade ended up items that meet market needs and consumer expectations. Supplying modification alternatives such as individualized designs, shade variants, and textural components can considerably boost the allure of in-mold decor items.

Report this page